From Tracks to Rollers: Checking Out a Variety of Komatsu Undercarriage Parts

Wiki Article

Reliable Solutions: Undercarriage Parts for Heavy Machinery

Quality undercarriage components play a considerable role in making sure the smooth procedure and longevity of heavy machinery. In this conversation, we will explore the value of investing in superior undercarriage parts, usual wear difficulties faced by heavy machinery drivers, the benefits of prompt replacements, guidelines for choosing reputable distributors, and important upkeep suggestions to extend the life-span of undercarriage elements.Significance of High Quality Undercarriage Components

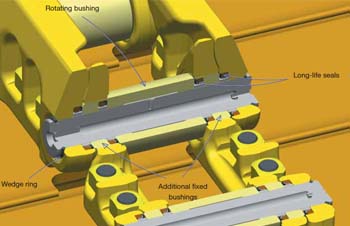

Quality undercarriage components are essential components in guaranteeing the toughness and efficiency of hefty equipment. The undercarriage of tools such as excavators, excavators, and track loaders plays a critical role in supporting the machine's weight, providing stability on various surfaces, and soaking up the influence of irregular surface areas. By purchasing top notch undercarriage components, operators can considerably extend the lifespan of their machinery and lower the threat of unanticipated break downs.One key benefit of making use of top quality undercarriage components is the enhancement of overall equipment efficiency. Long lasting tracks, sprockets, idlers, and rollers lower rubbing and guarantee smoother movement, inevitably bring about boosted efficiency and effectiveness on task websites. Trusted undercarriage elements reduce downtime for upkeep and repair work, allowing operators to optimize their operational hours and task due dates.

Common Undercarriage Use Issues

Advantages of Timely Substitute

One key advantage of timely undercarriage component replacement is boosted equipment uptime. By changing used parts before they fall short, the threat of unforeseen malfunctions is lessened, decreasing downtime for repair services and upkeep. This proactive approach not just maintains the heavy equipment functional but also protects against prospective damage to various other elements that could arise from a stopping working undercarriage.

Furthermore, replacing undercarriage components quickly can improve total efficiency. A well-maintained undercarriage makes certain ideal machine efficiency, enabling smoother procedure and higher performance in finishing tasks. This, subsequently, leads to raised task site efficiency and cost financial savings by avoiding hold-ups and disruptions triggered by underperforming machinery. Consequently, investing in prompt undercarriage part substitute is a proactive method that pays off in terms of boosted efficiency and minimized operational expenses.

Choosing the Right Undercarriage Provider

Choosing the ideal undercarriage supplier is an essential choice that considerably affects the efficiency and upkeep of hefty equipment. When picking a supplier for undercarriage parts, several elements need Home Page to be taken into consideration to ensure optimal efficiency and cost-effectiveness. Firstly, it is necessary to examine the vendor's online reputation and experience in the sector. A reliable provider with years of experience is most likely to provide top quality parts and reliable solution. In addition, take visit this site into consideration the series of products offered by the supplier. A supplier that supplies a large choice of undercarriage parts for various hefty equipment brands and designs can be beneficial as it supplies a lot more choices to satisfy certain needs.Moreover, assessing the distributor's client service and support is vital. A supplier that offers exceptional client service, fast response times, and technological aid can assist decrease downtime and ensure smooth operations. Price is also a considerable variable to consider; nevertheless, it must not be the single determinant. When picking the right undercarriage provider for heavy machinery, balancing integrity, cost-effectiveness, and top quality is vital. By meticulously reviewing these variables, you can pick a distributor that fulfills your needs and adds to the effective performance and maintenance of your heavy equipment.

Maintenance Tips for Extended Lifespan

To make certain a prolonged lifespan for hefty machinery undercarriage parts, carrying out a positive upkeep regimen is important. Routinely inspecting undercarriage parts such as track chains, idlers, rollers, and sprockets for damage is important. Any indications of damage or excessive wear should be without delay dealt with to avoid additional deterioration and possible failures. In addition, keeping the undercarriage tidy from dust, debris, and harsh materials can substantially prolong its life expectancy. Greasing moving components according to manufacturer suggestions aids decrease rubbing and prevent premature wear. Checking track tension and positioning is additionally important to stop uneven wear on the undercarriage elements. Buying quality undercarriage parts from reputable providers is just as important for guaranteeing durability. By adhering to these upkeep tips carefully, hefty equipment proprietors can optimize the performance and toughness of their undercarriage components, inevitably reducing downtime and operational costs.Conclusion

In conclusion, top quality undercarriage components are necessary for the reliable operation of heavy equipment. Prompt substitute of worn parts can protect against pricey downtime and preserve ideal performance. Picking a trusted vendor and complying with proper upkeep techniques are essential to guaranteeing the extended life-span of undercarriage elements. By addressing usual wear problems and click here to read investing in high-quality parts, hefty machinery drivers can make best use of efficiency and minimize upkeep expenses.

Extreme wear and tear on undercarriage parts of hefty equipment can lead to considerable operational obstacles and boosted maintenance costs. Normal assessments, proper upkeep, and prompt replacements of used undercarriage components are vital to reduce these usual wear issues and guarantee the ideal functioning of hefty machinery.

A provider that offers a large selection of undercarriage components for different heavy machinery brands and versions can be useful as it provides more alternatives to meet particular requirements.

By complying with these maintenance tips carefully, heavy machinery owners can maximize the performance and longevity of their undercarriage components, eventually lowering downtime and operational expenses.

Report this wiki page